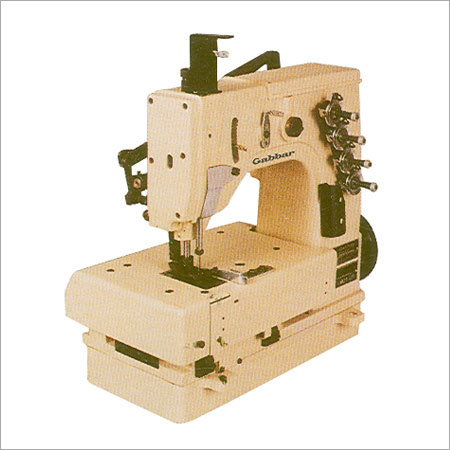

PP Jute Bag Closing Machine

PP Jute Bag Closing Machine Specification

- Product Type

- Bag Closing Machine

- General Use

- Sealing and stitching PP and Jute bags

- Weight (kg)

- 11 kg

- Type

- Portable

- Drive Type

- Belt Drive

- Bag Type

- PP, Jute Bag

- Computerized

- No

- Power

- 220W

- Voltage

- 220V/50Hz

- Material

- Cast Aluminium, Mild Steel

- Dimension (L*W*H)

- 380 x 250 x 320 mm

- Color

- Blue & Silver

- Thread Type

- Synthetic or Cotton

- Noise Level

- Low

- Operation

- Handheld

- Lubrication System

- Manual Lubrication

- Application

- Fertilizer, Sugar, Rice, and Grain Bags

- Needle Type

- Standard 80800 Needle

About PP Jute Bag Closing Machine

With more than 4 decades of industry expertise, we have been able to manufacture, export and supply Bag Closing Machine. This machine is widely demanded in various industries for the hassle-free and automated closing of open ends of bags after filling of materials. The offered machine is manufactured in sync with international standards using supreme quality components and avant-garde techniques. Furthermore, our valuable clients can avail this Bag Closing Machine from us in different technical specifications at affordable prices.

Technical Specifications:

|

Model |

Model AS 800 ATC |

Model AS 802 ATC |

|

No. of Needle |

Single |

Double |

|

Seam |

Double Thread Chain Stitch |

Four Thread Chain Stitch |

|

Speed |

800 - 900 Bags / hr |

800 - 900 Bags / hr |

|

Stitch Width |

5 - 9 mm |

5 - 9 mm |

|

Needle |

DRX2 - 26 (Orgen/Groze-BECKERT) |

DRX2 - 26 (Orgen) |

|

Start / Stop |

Photo-Switch |

Photo-Switch |

|

Cutter Type |

Air Cylinder Driven Guillotine Cutter |

Air Cylinder Driven Guillotine Cutter |

|

Air Pressure |

6Kg. / cm2 |

6Kg. / cm2 |

|

Air Consumption |

250 Lit. / min |

250 Lit. / min |

|

Photo Cell Range |

Upto 500 mm |

Upto 500 mm |

|

Infeed System |

0.25 H.P., 3 Phase, 4 Pole |

0.25 H.P., 3 Phase, 4 Pole |

|

Drive Motor |

For Sewing Head 0.5 H.P., 3 Phase |

For Sewing Head 0.5 H.P., 3 Phase |

|

For Conveyor 1 H.P., 3 Phase |

For Conveyor 1 H.P., 3 Phase |

|

|

Conveyor |

Slat or Belt Type |

Slat or Belt Type |

|

Lubrication System |

Auto Lubricating Pump |

Auto Lubricating Pump |

Versatile Application for Industrial Needs

This bag closing machine is well-suited for sealing a variety of industrial bags, including those used for fertilizer, sugar, rice, and grains. Its compatibility with both PP and jute bags ensures flexibility and efficiency in bulk packaging environments, making it an ideal choice for exporters, manufacturers, and suppliers across India.

Efficient and Durable Construction

Engineered with a robust cast aluminium and mild steel frame, this machine offers durability and reliable operation. The belt drive and standard needle allow for consistent stitching, while the manual lubrication system keeps maintenance simple and manageable for users.

FAQs of PP Jute Bag Closing Machine:

Q: How does the handheld PP Jute Bag Closing Machine operate?

A: This machine is operated manually and designed for portability, enabling users to easily seal and stitch bags at various locations. Its belt drive system, combined with a standard 80800 needle and compatibility with synthetic or cotton thread, ensures efficient and reliable operation.Q: What types of bags can this machine seal and stitch?

A: The machine is specifically made for PP (polypropylene) and jute bags and is used extensively in packaging fertilizers, sugar, rice, and grains. Its adaptable design accommodates various bag thicknesses commonly found in these industries.Q: When is manual lubrication required for this machine?

A: Manual lubrication should be performed at regular intervals based on usage frequency to ensure smooth operation and longevity of moving parts. Check the user manual for recommended maintenance schedules.Q: Where can this portable machine be used?

A: Due to its lightweight (11 kg) and compact dimensions, the machine can be used both on production floors and in storage or warehousing areas. Its especially valuable for on-site bag closing tasks in agricultural, processing, and export locations.Q: What is the process of bag closing with this machine?

A: To close a bag, position the filled bags open end under the machine, engage the stitching mechanism, and guide the bag through. The machine will seal and stitch the edge using the chosen thread and standard needle, ensuring a secure closure.Q: How is this machine beneficial to users?

A: Its low noise level ensures a comfortable work environment, while the portable, durable construction allows for flexibility and long-term value. Its engineered for ease of use and minimal computerization, streamlining bag closing operations for large-scale packaging.Q: What materials is the machine made from, and why?

A: The machine is made from cast aluminium and mild steel for optimal strength and resistance to wear. This construction ensures the machine can handle repeated industrial use while remaining portable and easy to maintain.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bag Closing Machine Category

Jumbo Bag Closing Machine

Price 65000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Other, Industrial Sewing/Sealing Machine

Product Type : Jumbo Bag Closing Machine

General Use : Bag Closing for Jumbo/PP/Woven Sacks

Bag Type : Other, Jumbo Bag, FIBC Bag, HDPE/PP Woven Bag

HDPE Bag Closing Machine with Conveyor

Price 50000 INR

Minimum Order Quantity : 1 Number

Type : Other, Conveyor Type

Product Type : Bag Closing Machine with Conveyor

General Use : Sealing and closing HDPE bags in packaging operations

Bag Type : Other, HDPE, PP, Multiwall Paper Bags

Industrial Woven Bag Closing Machine

Price 130000 INR

Minimum Order Quantity : 1 Number

Type : Other, Portable Stitching Machine

Product Type : Industrial Woven Bag Closing Machine

General Use : Sealing and stitching woven bags for industrial packaging

Bag Type : Other, Woven Bag, Jute Bag, PP Bag, HDPE Bag

Bag Closing Machine

Price 130000 INR

Minimum Order Quantity : 1 , , Number

Type : Other

Product Type : Bag Closing Machine

General Use : Yes

Bag Type : PP Bags

|

GABBAR ENGINEERING CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry