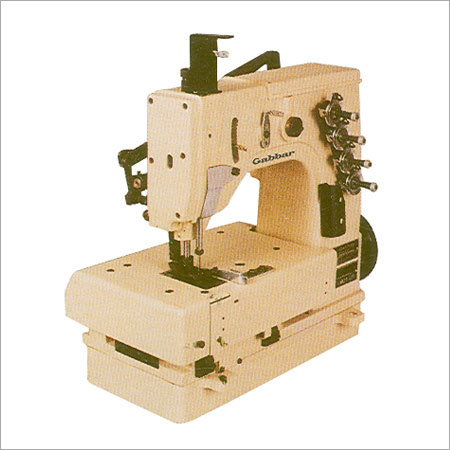

Industrial Woven Bag Closing Machine

Industrial Woven Bag Closing Machine Specification

- Product Type

- Industrial Woven Bag Closing Machine

- General Use

- Sealing and stitching woven bags for industrial packaging

- Type

- Portable Stitching Machine

- Drive Type

- Electric Motor Driven

- Bag Type

- Woven Bag, Jute Bag, PP Bag, HDPE Bag

- Computerized

- No

- Power

- 220 W

- Voltage

- 220 V

- Heater

- No

- Material

- Aluminum Body with Steel Components

- Dimension (L*W*H)

- 420 mm x 240 mm x 360 mm

- Color

- Silver & Blue

- Mobility

- Handheld/Portable

- Operating Temperature Range

- 5°C to 40°C

- Thread Cutter

- Automatic Thread Cutting

- Needle Type

- DN x 1 (Industrial Standard)

- Sewing Speed

- Up to 1800 stitches/minute

- Stitch Type

- Double Thread, Double Chain Stitch

- Max Seam Thickness

- 10 mm

- Noise Level

- < 70 dB

- Lubrication System

- Manual Lubrication

About Industrial Woven Bag Closing Machine

With more than 4 decades of industry expertise, we have been able to manufacture, export and supply Industrial Bag Closing Machine. This machine is widely demanded in various industries for the hassle-free and automated closing of open ends of bags after filling of materials. The offered machine is manufactured in sync with international standards using supreme quality components and avant-garde techniques. Furthermore, our valuable clients can avail this Industrial Bag Closing Machine from us in different technical specifications at affordable prices.

| Model | Model AS 800 ATC | Model AS 802 ATC |

| No. of Needle | Single | Double |

| Seam | Double Thread Chain Stitch | Four Thread Chain Stitch |

| Speed | 800 - 900 Bags / hr | 800 - 900 Bags / hr |

| Stitch Width | 5 - 9 mm | 5 - 9 mm |

| Needle | DRX2 - 26 (Orgen/Groze-BECKERT) | DRX2 - 26 (Orgen) |

| Start / Stop | Photo-Switch | Photo-Switch |

| Cutter Type | Air Cylinder Driven Guillotine Cutter | Air Cylinder Driven Guillotine Cutter |

| Air Pressure | 6Kg. / cm2 | 6Kg. / cm2 |

| Air Consumption | 250 Lit. / min | 250 Lit. / min |

| Photo Cell Range | Upto 500 mm | Upto 500 mm |

| Infeed System | 0.25 H.P., 3 Phase, 4 Pole | 0.25 H.P., 3 Phase, 4 Pole |

| Drive Motor | For Sewing Head 0.5 H.P., 3 Phase | For Sewing Head 0.5 H.P., 3 Phase |

| For Conveyor 1 H.P., 3 Phase | For Conveyor 1 H.P., 3 Phase | |

| Conveyor | Slat or Belt Type | Slat or Belt Type |

| Lubrication System | Auto Lubricating Pump | Auto Lubricating Pump |

Engineered for Versatile Bag Closing

Whether you are in the agricultural, chemical, or food packaging sector, this double-threaded, double chain stitch portable machine ensures secure sealing of a variety of bag types, including woven, jute, PP, and HDPE bags. Its ergonomic, handheld design supports elevated productivity for mobile or stationary operations.

Precision and Durability Focused

Built with a resilient aluminum body and reinforced steel components, this machine provides consistent high-capacity performance. The manual lubrication system helps prolong machine life, while the automatic thread cutter streamlines workflow and increases efficiency.

FAQs of Industrial Woven Bag Closing Machine:

Q: How does the double chain stitch enhance bag sealing durability?

A: The double chain stitch forms two parallel rows of secure stitches using double threads, providing superior strength and reliability. This stitch type reduces the risk of seam breakage, making it well-suited for heavy-duty industrial bag sealing.Q: What types of bags can this portable machine close?

A: This machine is designed for stitching woven, jute, polypropylene (PP), and high-density polyethylene (HDPE) bags of up to 10 mm seam thickness, commonly used across various packaging industries.Q: Where can I utilize the Industrial Woven Bag Closing Machine?

A: Ideal for use in factories, warehouses, farms, and packaging facilities, its portable and lightweight build allows operators to move freely, sealing bags directly at the packaging site.Q: What is the process for operating the machine?

A: To operate, secure the bags open edge under the presser foot, power on the machine, and guide the bag as it stitches with the DN x 1 needle. The manual lubrication system requires regular oiling for smooth functioning, while the automatic thread cutter trims excess thread after each closure.Q: What are the main benefits of using this bag closing machine?

A: Key advantages include high sewing speed (up to 1800 stitches/minute), portable design, low noise operation (<70 dB), automatic thread cutting, and effective sealing for various industrial bag types, resulting in improved efficiency and product protection.Q: When is maintenance required for this machine?

A: Regular manual lubrication is necessary to ensure smooth operation and reduce wear. Routine checks and cleaning after extended use are recommended to maintain optimal working condition.Q: What safety or environmental conditions should be considered during use?

A: Operate the machine within a temperature range of 5C to 40C and ensure a stable power supply (220V). Its design limits noise exposure, contributing to a safer working environment.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bag Closing Machine Category

Jumbo Bag Closing Machine

Price 65000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Drive Type : Other, Electric Motor Driven

Product Type : Jumbo Bag Closing Machine

General Use : Bag Closing for Jumbo/PP/Woven Sacks

Bag Type : Other, Jumbo Bag, FIBC Bag, HDPE/PP Woven Bag

HDPE Bag Closing Machine with Conveyor

Price 50000 INR

Minimum Order Quantity : 1 Number

Drive Type : Other, Belt Driven

Product Type : Bag Closing Machine with Conveyor

General Use : Sealing and closing HDPE bags in packaging operations

Bag Type : Other, HDPE, PP, Multiwall Paper Bags

PP Jute Bag Closing Machine

Price 130000 INR

Minimum Order Quantity : 1 Number

Drive Type : Other, Belt Drive

Product Type : Bag Closing Machine

General Use : Sealing and stitching PP and Jute bags

Bag Type : Other, PP, Jute Bag

Bag Closing Machine

Price 130000 INR

Minimum Order Quantity : 1 , , Number

Drive Type : Electric

Product Type : Bag Closing Machine

General Use : Yes

Bag Type : PP Bags

|

GABBAR ENGINEERING CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry