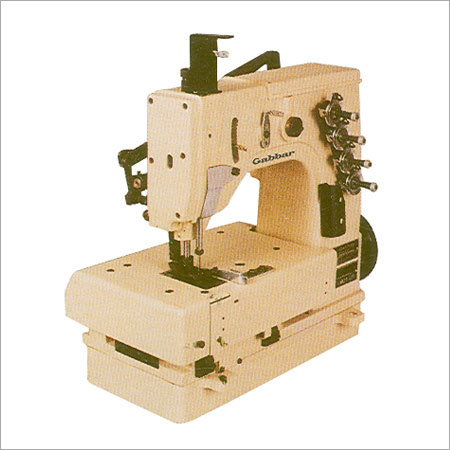

Jumbo Bag Closing Machine

Price 65000.00 INR/ Unit

Jumbo Bag Closing Machine Specification

- Product Type

- Jumbo Bag Closing Machine

- General Use

- Bag Closing for Jumbo/PP/Woven Sacks

- Capacity

- 400-600 bags per hour

- Weight (kg)

- 300 kg

- Automatic Grade

- Semi-Automatic

- Type

- Industrial Sewing/Sealing Machine

- Drive Type

- Electric Motor Driven

- Bag Type

- Jumbo Bag, FIBC Bag, HDPE/PP Woven Bag

- Computerized

- No

- Power

- 1000 W

- Voltage

- 220 V / 50 Hz

- Heater

- With Heater for Sealing

- Material

- Mild Steel (MS) Body

- Dimension (L*W*H)

- 1300 mm x 850 mm x 2000 mm

- Color

- Blue with Metallic Finish

- Thread Cutter

- Automatic Thread Trimming

- Sealing Type

- Double Needle & Double Thread

- Mobility

- Fitted with Castor Wheels for Easy Movement

- Control Panel

- User Friendly with Indicator

- Application

- Used in Fertilizer, Cement, Chemical, Agro-Industries

- Lubrication

- Automatic Oil Bath System

- Noise Level

- Low Noise Operation

- Sewing Speed

- Up to 18 m/min

- Working Height

- Adjustable

- Stitch Type

- Safety Stitch (Two Thread Chain Stitch)

Jumbo Bag Closing Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 1 Week

About Jumbo Bag Closing Machine

In the bag making process, closing bag is one of the major steps that can be performed speedily by using a high-tech machine. This jumbo bag closing machine is an ideal machine that can be utilized in small to large bag making companies for carrying out the job of closing bags. The strong and durable machine can close jumbo bags that can be used for packing animal feed, flour, cereals, charcoal, chemicals, fertilizers, to name a few. The machine makes low noise while sewing the bags at high speed.Advanced Stitching & Sealing Technology

This industrial sewing machine employs a double needle, double thread safety stitch mechanism to ensure every bag is securely sealed. An integrated heating unit further enhances the sealing process, making it ideal for sectors needing dust-proof, tamper-resistant closures. Automatic thread trimming accelerates operations while reducing manual effort.

User-Centric Design & Mobility

The machine is thoughtfully engineered with a user-friendly control panel, complete with indicator lights for simplified operation. Adjustable working height accommodates various bag sizes, and the sturdy castor wheels provide excellent mobility within factory premises, ensuring seamless integration into any production line.

Optimal Performance & Durability

Equipped with a 1000 W electric motor, this machine delivers impressive sewing speeds of up to 18 meters per minute. Its automatic oil bath lubrication system and mild steel construction guarantee longevity, while its semi-automatic design balances automation and operator control for consistent, high-capacity use.

FAQs of Jumbo Bag Closing Machine:

Q: How does the double needle and double thread system benefit bag closing?

A: The double needle, double thread setup creates a robust safety stitch (two thread chain stitch), enhancing seam strength and ensuring bags remain securely closed even under heavy loads or during transport. This is particularly essential for industrial materials such as fertilizers, cement, and chemicals.Q: What types of bags can this machine handle, and in which industries is it most commonly used?

A: This machine is suitable for closing jumbo bags, FIBC bags, and HDPE/PP woven sacks. It is widely adopted in industries such as fertilizer, cement, chemicals, and the agro sector, where safe and reliable packaging is critical for both storage and transportation.Q: How is the machine moved and set up within a facility?

A: The machine is fitted with durable castor wheels, making it easy to move around the factory floor. Its adjustable working height also means it can be quickly configured to fit different bag sizes and production setups, enhancing workflow flexibility.Q: What maintenance does the automatic oil bath system require?

A: The automatic oil bath system ensures all moving parts are consistently lubricated, minimizing wear and extending machine life. Operators simply need to monitor oil levels and refill as necessary, significantly reducing regular maintenance tasks.Q: When should you use the heater function for sealing?

A: The heater is used during the sealing process of bags that require an airtight and tamper-proof closurecommon for materials sensitive to moisture or contamination. Activate the heater as specified in the control panel before processing these types of bags.Q: What makes the control panel user-friendly?

A: The control panel features intuitive indicator lights and straightforward controls, making it easy for operators to monitor machine status, adjust settings, and control the operation with minimal training.Q: What is the process for closing a bag using this machine?

A: Bags are positioned on the machine, and after adjusting the working height if needed, the machine automatically applies a safety stitch using double needles and threads. The automatic thread trimmer and heater then finalize the closure, resulting in a secure, sealed package.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bag Closing Machine Category

HDPE Bag Closing Machine with Conveyor

Price 50000 INR

Minimum Order Quantity : 1 Number

Bag Type : Other, HDPE, PP, Multiwall Paper Bags

Type : Other, Conveyor Type

General Use : Sealing and closing HDPE bags in packaging operations

Drive Type : Other, Belt Driven

Industrial Woven Bag Closing Machine

Price 130000 INR

Minimum Order Quantity : 1 Number

Bag Type : Other, Woven Bag, Jute Bag, PP Bag, HDPE Bag

Type : Other, Portable Stitching Machine

General Use : Sealing and stitching woven bags for industrial packaging

Drive Type : Other, Electric Motor Driven

PP Jute Bag Closing Machine

Price 130000 INR

Minimum Order Quantity : 1 Number

Bag Type : Other, PP, Jute Bag

Type : Other, Portable

General Use : Sealing and stitching PP and Jute bags

Drive Type : Other, Belt Drive

Bag Closing Machine

Price 130000 INR

Minimum Order Quantity : 1 , , Number

Bag Type : PP Bags

Type : Other

General Use : Yes

Drive Type : Electric

|

GABBAR ENGINEERING CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry