Most Popular Products

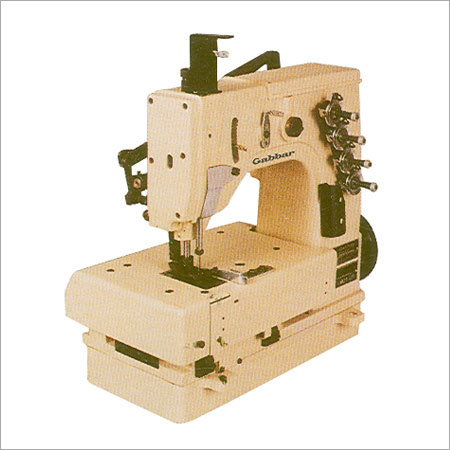

Big Bag Sewing Machine

MOQ : 1 Number

Big Bag Sewing Machine Specification

- Feed Mechanism

- Compound Feed

- Dimension (L*W*H)

- 60 x 35 x 55 cm

- Needle

- DBx1 / 25#

- Stitch width

- 7 mm

- Operate Method

- Motor Driven

- Sewing Thickness

- Up to 8mm

- Condition

- New

- Stitch Length

- 0-13 mm Adjustable

- Product Type

- Big Bag Sewing Machine

- Voltage

- 220V / 50Hz

- Power

- 550W

- Color

- White & Blue

- Sewing Speed

- 1200 SPM

- Stitch Formation

- Lock Stitch

- Accessories

- Tool Kit, Oil Can, Instruction Manual

- Bobbin System

- Large Bobbin Capacity

- Usage

- Industrial

- Needle Bar Stroke

- 38 mm

- Application

- Suitable for FIBC, Jumbo Bags, Big Bag, PP Woven Bags

- Weight

- 45 Kg

- Thread Type

- Synthetic / Cotton

- Packing Type

- Wooden Box / Carton Box

- Max Bag Height

- 1200 mm

- Motor Type

- Clutch or Servo Motor

- Body Material

- Cast Iron & Steel

- Lubrication

- Automatic

- Noise Level

- Low

About Big Bag Sewing Machine

Technical Specification

| Model | ST602HR, ST603UDR-N, ST802VMC, LS1500LB |

| Usage/Application | Heavy Material |

| Max Sewing Speed | 3000-4000 (stitch/min) |

| Automation Grade | All |

| Bag Material | HDPE |

| Machine Type | Big Bag Sewing Machine |

| Brand | Gabbar Engineering |

High Performance for Industrial Bag Production

Built to handle the rigorous demands of industrial environments, the Big Bag Sewing Machine excels in stitching large bags for various sectors. Its solid cast iron and steel body, combined with automatic lubrication and low noise operation, guarantees durability and user comfort. The adjustable stitch settings and large bobbin capacity further contribute to smooth and productive workflows, essential for manufacturers and suppliers alike.

Flexible Application and Reliable Stitching

This sewing machine is suitable for FIBC, Jumbo, and PP woven bags, making it ideal for industries dealing with bulk packaging solutions. The lock stitch formation and compound feed mechanism deliver strong, secure seams, while compatibility with both synthetic and cotton thread offers versatility. With a maximum sewing thickness of 8mm and adjustable stitch lengths, it accommodates a wide range of bag sizes and materials.

FAQs of Big Bag Sewing Machine:

Q: How does the Big Bag Sewing Machine ensure low noise during operation?

A: The machine is constructed with precision engineering and quality materials, including cast iron and steel. Its design incorporates components that minimize vibration and dampen sound, resulting in lower noise levels for more comfortable, continuous use in industrial settings.Q: What types of bags can be sewn with this machine?

A: This sewing machine is suitable for FIBC (Flexible Intermediate Bulk Containers), Jumbo Bags, Big Bags, and PP Woven Bags. Its versatile design and large bobbin capacity make it ideal for handling various bulk packaging products used across industries.Q: When is the best time to use the Big Bag Sewing Machine in production?

A: The Big Bag Sewing Machine is most effective during the final assembly or closing stages of bag manufacturing, when secure, durable stitches are needed for heavy-duty bags. It is ideal for production runs requiring consistent lock stitches and high output speed.Q: Where is the Big Bag Sewing Machine typically installed?

A: The machine is designed for industrial use and is typically installed in manufacturing plants, packing houses, or facilities specializing in bulk bag and container production. Its compact dimensions and motor-driven operation allow for convenient placement on factory floors.Q: What is the process for setting up and operating this sewing machine?

A: Setup involves unpacking the machine from its wooden or carton box, assembling included accessories such as the tool kit and oil can, and connecting the motor to a 220V/50Hz power supply. Automatic lubrication ensures smooth operation, and stitch settings can be adjusted to align with specific bag requirements. Detailed instructions are provided in the manual for startup and maintenance.Q: Which benefits do users gain from using the Big Bag Sewing Machine?

A: Users benefit from enhanced productivity, reliable stitching strength, and reduced maintenance thanks to automatic lubrication and robust construction. The machines versatility in thread types and stitch adjustments allows for customization, while its low noise output fosters a better working environment.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Big Bag Sewing Machine Category

ST 602 HR FOR Jute Bags Machine

Price 80000 INR / Set

Minimum Order Quantity : 1 Set

Operate Method : Electric

Condition : New

Power : 1 Horsepower (HP)

Product Type : JUTE BAG SEWING MACHINE

ST 1000 LA Sewing Machine

Price 200000 INR / Set

Minimum Order Quantity : 1 Set

Operate Method : Manual

Condition : New

Power : 1 Horsepower (HP)

Product Type : FIBC BAG SEWING MACHINE

|

GABBAR ENGINEERING CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry